Challenge

A global manufacturer of electric mining shovels required a reliable performing motor for their dipper system. Mining shovel owners and manufacturers require a dipper trip control system that works consistently with low maintenance.

Application requirements:

- High peak torque, extreme duty cycles and operation in critical environments

- Explosion proof, UL & ATEX required

- Efficient and energy sound solutions include power density and thermal management

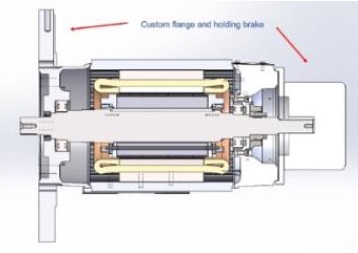

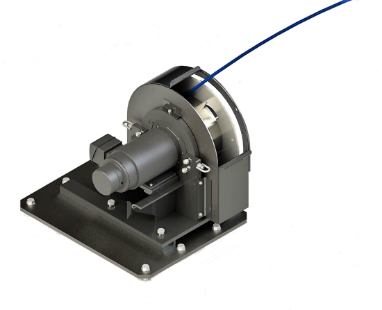

- Flexibility for custom application solutions i.e., mounting flexibility, custom flanges, holding brake, etc.

- Fast response across speed range

POWERTEC Solution

POWERTEC PACTORQ® Brushless Motors Features & Specifications

- Optimized magnetic design

- Neodymium, Samarium and Ferrite magnets

- Long life bearings with grease

- NEMA enclosures with metric mounting options

- Rugged IGBT class “H” insulation system and rated for class “F” temperature rise

- Flexible design incorporates many options

- UL recognized, CE (Conformity European)

- Meets IEC requirements

- Designed, double finned aluminum frame

- Temperature range of -40°C to +160°C

Benefits

- Compact power dense design for installations with limited space availability without compromising performance

- Virtually zero losses due to rotor induction currents, reducing energy use and cost

- Accurate speed and torque control, no losses due to slip

- Longer service life: reduced maintenance time results in

cost savings and less downtime

RESULTS

POWERTEC has been supplying these motors to the manufacturer for more than a decade with benefits:

- Reduced cycle time with reliable door trips.

- More loaded haul trucks per shift help lower cost per ton for the shovel owners.

- Mining shovels with POWERTEC motors help provide a reliable trip and slack take up operation.